Part 2: Hydraulic Test Stand Advantages

Now that you know how a test stand works, you might be wondering why HPS would invest in one.

That’s an easy answer for us. Because it creates a superior product.

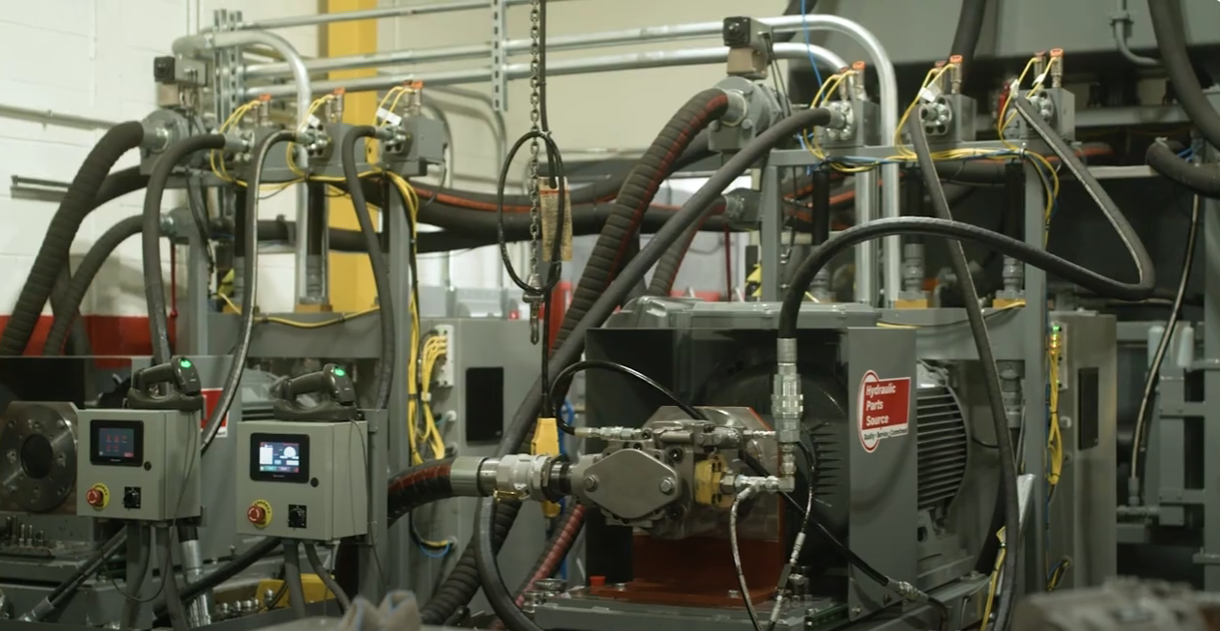

HPS uses a stand that is unmatched in our field, allowing us to perform quality testing on all products before they leave our building, and ensuring they all meet or exceed OEM specifications in various fluid power settings and configurations.

Our cutting-edge automated test stand is a game-changer when it comes to quality.

Why This new technology scans every product before testing, enables the test stand to automatically set parameters that mirror OEM standards and ensures a product is as close to perfection as possible before it reaches its end-user.

Benefits of Testing

Analyzing hydraulic power system design, power, pressure flow rates, and mechanism of circuitry are all important factors when testing hydraulic components.

A test stand provides a useful tool for illustrating the functionality of pressure reducing, and directional control valves. By analyzing the fluid mechanics of the hydraulic system, we can apply hydraulic power and fluid analysis theoretically and validate experimentally, and pass the data onto you.

You also should expect to get some big benefits with this testing and the resulting data, including:

- Shortened troubleshooting time

- Accurate diagnosis and identification of any problems with components

- Tested rebuilt parts for proper operation

- Improved customer satisfaction

- Avoidance of unnecessary expensive repair work (often an inexpensive solution is found) and downtime

- Taking the guesswork out of diagnoses

HPS Test Stand Like no Other

We knew that investing in a test stand would produce better-quality products, but we didn’t stop there.

Our test stand is unique in that it:

- Is fully automated, removing the risks associated with manual testing

- Stores data via IO-Link protocol and an industrial PC, which is also linked to orders for traceability

- Reduces human error and variability

- Has broad capabilities, ranging up to 100 horsepower, 100 gallons per minute, and 4,000 PSI (range is typically between 200 and 5,000 psi)

Our test stand allows us to test all sizes of pumps, no matter how small or large.

With Hydraulic Parts Source, end-users are not just getting a re-manufactured pump or valve – they're getting the promise of seamless production restoration, minimal downtime, and maximum profitability.

This is part two of a two-part series. For more information about our new test stand, and why it creates a superior quality worthy of the HPS lineup, see Part 1 or check out our video at https://www.youtube.com/watch?v=CfqqrohAEVk