As valuable resources for end-users, distributors are often the providers of support and knowledge when it comes to the products they sell.

Fluid power distributors can meet their customers’ needs with their knowledge of hydraulic pumps, motors, and valves.

But let’s back up a minute and think of how these components fit into the system as a whole and provide a simple overview.

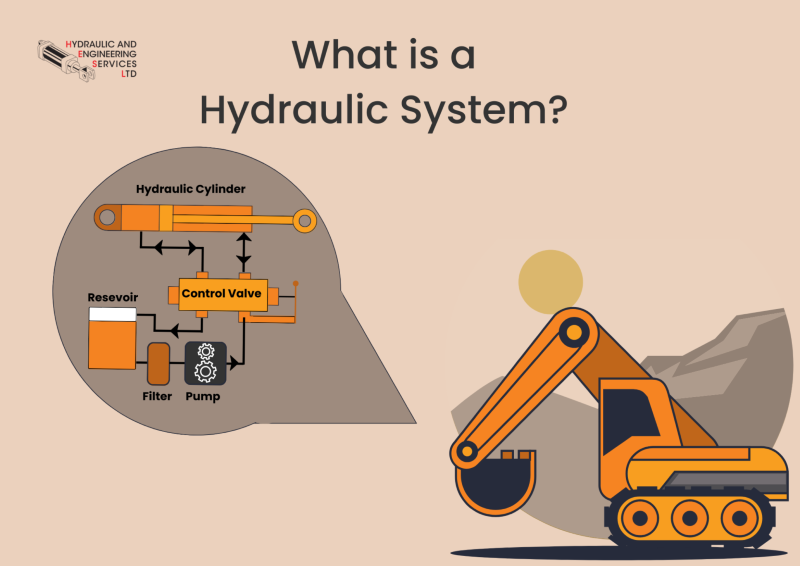

A hydraulic system is simply a conglomerate of components that perform the function of using pressurized fluid to perform tasks, most commonly for use in heavy equipment.

From Hydraulic and Engineering Services LTD

Every system that transfers energy using pressurized incompressible hydraulic fluids is a hydraulic system.

Advantages of hydraulic power transmission include:

- Control accuracy

- Quieter operations

- Ease of control

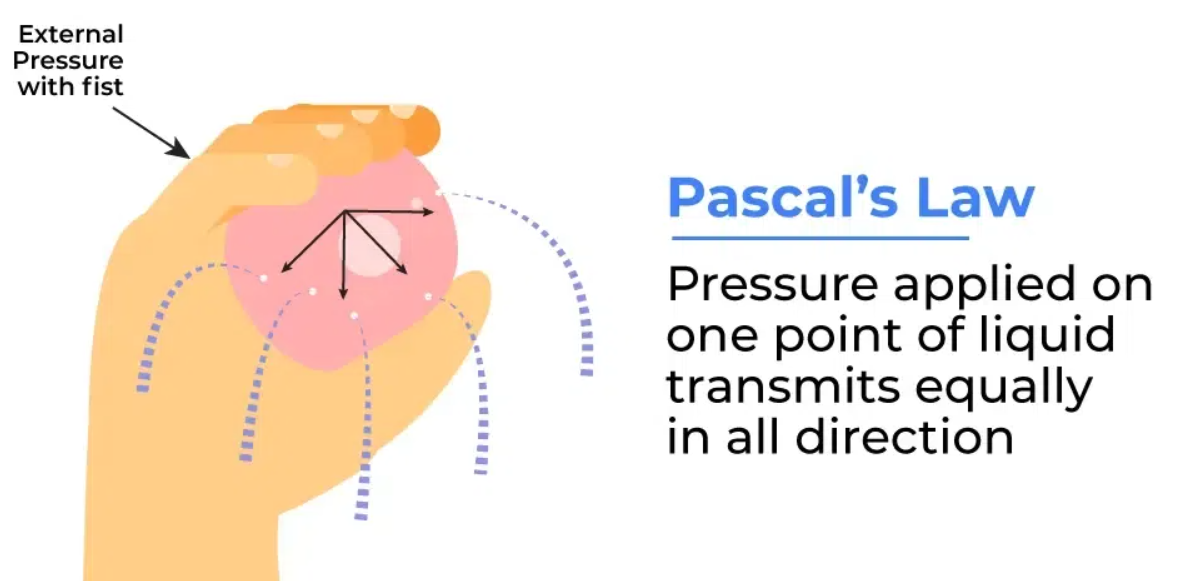

Applying Pascal’s Law, hydraulic power enables the operator to accomplish significant work with a minimum investment.

Pascal’s Law?(also?known as Pascal’s Principle or the?principle of transmission of fluid pressure) is a principle in?fluid mechanics?that states that?a?pressure?change in one part of a closed container is?transmitted?without loss to every portion of the fluid and to the walls of the container.

Basic knowledge about hydraulic systems may be worth a refresher, so let’s break down how these versatile systems are composed and operate.

Types of Hydraulic Systems

Hydraulic systems can be divided into two categories, open- and closed-loop systems.

Fluid flows continuously between the pump and the actuator without entering the reservoir in a closed-loop system.

An open-loop system operates with fluid flow from the actuator to the reservoir and then toward the pump inlet using directional control valves.

Open-loop hydraulic systems are used for simple, low-pressure applications (below 3000psi), while closed-loop systems are used for complex, high-pressure applications with less fluid flow.

Open-loop hydraulic systems generate less heat, while closed-loop hydraulic systems provide a more precise response to actuation.

Examples of open-loop hydraulic systems include:

- Turbines

- Compressors

- Pumps

- Boilers

- Heat exchangers

Examples of closed-loop hydraulic systems include:

- The internal combustion engine

- Bomb calorimeter

- Reciprocating air compressor

- Refrigerating systems

Components Vital to Hydraulic Systems

There are several components in a system that are considered critical when applying Pascal’s Law in the operation of hydraulic equipment.Transferring fluids directly through a pipeline won’t create any hydraulic pressure, so the system needs a variety of components, including:

- Pumps

- Reservoirs

- Actuators

- Valves

- Filters

The system is dependent on this conversion of power for it to function.

There are three major types of pumps in a hydraulic system:

- Gear pumps?are economical, reliable, durable, and easy to install. The disadvantages are that they become inefficient over time, and they tend to be noisy when operating. A major advantage is that they are more tolerant of contamination. There are two common types of gear pumps: internal and external. Internal gear pumps offer a wide viscosity range of up to 2200 cSt and are generally quiet with a high efficiency even at low fluid viscosity. External gear pumps can handle pressures up to 3000 to 3500 psi and offer a fixed displacement delivery to a system at lower viscosity ranges limited to less than 300 cSt.

- Vane pumps?are more efficient than gear pumps, but less efficient than piston pumps. Advantages include many control options (such as pressure compensation, load sensing, and displacement controls) and?less noisy. In their many variations, van pumps work similarly in that a slotted rotor is coupled to the drive shaft and turns inside of a cam ring. Vanes inside the rotor slots follow the inner surface of the cam ring as the rotor turns.

- Piston pumps?are capable of high pressure, are efficient (95%), and have nearly infinite control methods. The downsides? These pumps are higher cost when it comes to both purchase and repair. They require complex service, which is unfortunate considering?the mechanical parts in a piston pump?are also more prone to wear. Piston pumps can operate at pressures beyond 6000 psi and produce comparatively little noise.

They can redirect pressurized fluid, control the level of flow to a certain area, or completely close a line.

There are three major types of hydraulic valves:

- Pressure Control Valves are used to regulate the fluid pressure that is passing through hydraulic systems and prevent rises in pressure that may result in system problems. They are also used to maintain a set pressure in a part of a hydraulic circuit.

- Flow Control Valves control flow rates in hydraulic circuits, with the end goal of controlling speed elsewhere in a fluid power system.

- Directional Control Valves have three main functions: to stop fluid flow, to allow fluid flow, or to change the direction of fluid flow between hydraulic cylinders and motors.

Systems and Components Overview

A hydraulic system is made up of components that are needed to use pressurized fluid to perform tasks, most commonly in heavy equipment.

Every system that transfers energy using pressurized incompressible hydraulic fluids is a hydraulic system, and that power is controlled and flexible for the work needed.

Through the application of Pascal’s Law, hydraulic power enables the operator to accomplish significant work with a minimum investment.

Whether a closed- or open-looped hydraulic system, knowing the basics allows for big-picture decisions to be made about end-user needs.

Hydraulic Parts Source is a leading fluid power remanufacturer, and we’re ready to serve you. Contact us today to experience OE quality for a fraction of the time and cost by calling (888) 477-7278 or get a quote by emailing sales@hydparts.com.