How Do Directional Control Valves Work?

Valves have a unique ability to control fluid within a hydraulic system.

Directional Control Valves (DCVs) do so by directing the path of hydraulic fluid (flow) through a circuit. They are used to start, stop, slow, accelerate, and change the direction of motion in a cylinder.

The internal control element of a DCV (sliding spool, rotary spool, or ball) is designed for all these applications.

One of the most common valve types are Sliding Spool Valves. They have different flow path configurations depending on the sliding spool design. All these sliding spool flow paths are found within the same body. Externally they look the same, internally they are different.

It is this construction that allows them to stop or shift flow suddenly, and are sometimes referred to as either “switching” or “bang-bang” valves for the sound they make when doing so.DCVs are also more formally called discrete valves, referring to how the valves shift from one discrete position to another.

When Are Directional Control Valves Used?

DCVs are essential with any hydraulic circuits to create bi-directional motion for a hydraulic actuator, or anything with a motor is going to benefit from their use, as they can be actuated into a variety of discrete positions for many functions.

Their usefulness derives from this process of actuation, or the movement of the valve from one position to another. Actuation makes DCVs vital instruments in controlling flow within complex hydraulic systems.

They work to actuate using these four methods:

- Manual

- Mechanical

- Solenoid-Operated

- Pilot-Operated

Some other examples of DCV usage include:

- To isolate a branch of the circuit

- To vent the relief valve

- To allow free flow from the pump to the reservoir

- How Does a DCV Work?

The valve will shift to perform the operation and then shift back to the neutral position when completed. This action occurs instantaneously, causing fluid to accelerate and decelerate.

How the operation plays out specifically depends on variations in spool-type, spool positioning, and method of control.

Check valves, for example, are binary directional control valves that allow fluid to flow in one direction while preventing it to flow in the opposite direction.

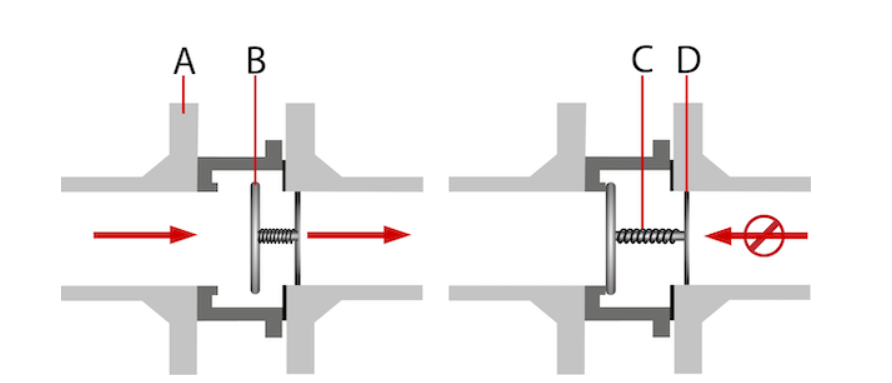

Spring-loaded check valves work like this:

- The flow enters the input port and the pressure pushes the disc open (A-B)

- The spring closes the disc after enough back pressure is reached (C-D)

Source: tameson.com

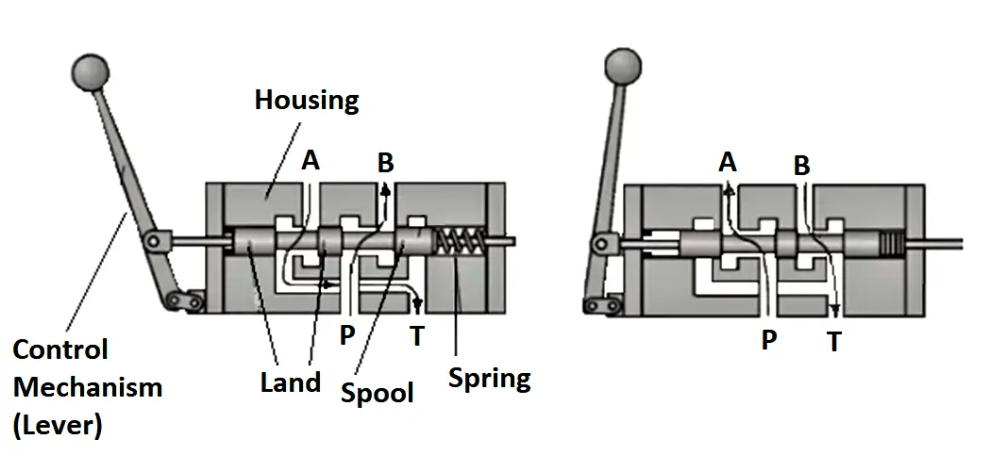

Spool-type valves are more complex, and that complexity has proven to be useful in complex hydraulic systems.

For example, levers on spool valves have the option of shifting to two or more positions for routing fluid between inlet and outlet ports, which are sometimes referred to as “ways.”

The various options that exist between number of ports and spool positions (ways) can be used for specific control of actuators.

The most common directional control valve is a 4/3-way valve (four ports/three spool positions).

Let’s take a look at the simpler 4/2-way directional control valve, in which the two positions of the spool lever simply allow or restrict flow. The valve is encased in housing for precision.

Here’s how they work:

- Open position: A lever’s position allows flow as designed (left)

- Closed position: The lands are shifted to restrict flow (right)

DCV Troubleshooting and Resources

Directional control valves keep fluid in a standby mode, preventing its flow from within the system until it’s needed to move and perform its designed function.This can be extremely useful but also the intricacies of their mechanics can occasionally cause issues, including contamination.

The best way to avoid DCV problems, or failure, is to prevent system contamination.

Keeping the oil clean, cool, and dry (preventing water contamination) will prevent most DCV failures and promote the longevity of the DCVs in the hydraulic system.Keeping these useful valves controlling the path of hydraulic fluid, and performing their vital start, stop, slow, accelerate, and change functions by providing proactive care and reaching out for repair resources is worth the effort.

Hydraulic Parts Source is a great resource to fulfill your Servo/Proportional valve repair and replacement needs – in any brand of valve you can find. Visit Hydparts.com for a full list of valves we service, or contact us to get a quote.